Rocklin Manufacturing Blog

Introducing The Rocklinizer Model 950

For a large portion of our company’s 83-year history, we have manufactured the Rocklinizer Carbide Application Equipment to help companies around the world alleviate metal-on-metal wear, enhance gripping, and improve maintenance for their metals, tools and dies. Through our proprietary electronic spark deposition process, our customers minimize machine downtime while delaying or even avoiding expensive new equipment purchases. In short, a modest investment in the Rocklinizer typically saves our customers several multiples in both time and money.

The Model 850 was our fastest Rocklinizer with the widest deposit range from .0002” to .007”, all controllable within .0001” by machine setting to suit our customers’ needs with precision. The Model 850 is used to solve wear and gripping problems spanning a broad range of ever-increasing applications, including: die casting dies, punching, stamping, extruding, bending dies, collets, cutting blades, bearings, and countless others.

But what if we could build a model that would coat large parts and dies even faster? What if we could add an even heavier deposit to aid our customers clamoring for rougher surfaces for gripping? And what if we could improve usability through a newly designed rotary applicator?

Our elite engineering team was up to the challenge. Through an extensive R&D process, we are proud to introduce the Model 950, our fastest Rocklinizer with the widest range of deposit capabilities yet, all housed in a sleek unit and applicator combination. In other words, this is the only Rocklinizer you will ever need.

Let’s look at the Model 950 across the following dimensions: speed, deposit range, and usability.

Speed

The Model 950 uniformly coats a 5 sq. in. area in less than 1 minute, which is substantially faster than previous models. For our customers Rocklinizing large dies for sometimes several hours at a time, this time savings drives immense cost savings and efficiency gains. Meanwhile, for more delicate jobs, the application speed can be slowed down by machine setting.

Deposit range

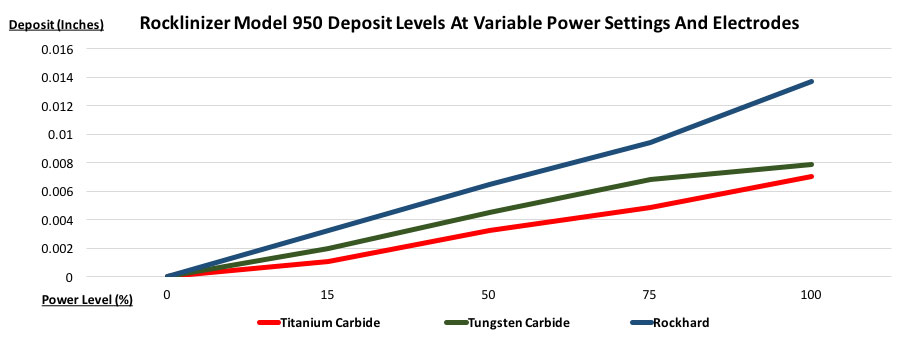

The Model 950 maintains the lower end capabilities found on prior Rocklinizer models with deposit amounts as little as .0001”. But could we realize heavier deposits well above what we achieved in the past? As you can see in the graph below, the answer is a resounding yes:

While deposit levels will vary depending on the base material, these tests on tool steel illustrate the amounts that can be achieved by each of our three electrodes: titanium carbide, tungsten carbide, and Rockhard. With deposit capabilities well exceeding .010” and the ability to control within .0001” by machine setting, unlimited wear, gripping, and maintenance applications are at your fingertips.

Usability

We developed two new features for the 950 to improve usability. The first is a new rotary applicator designed to enhance ease of use and control vs. our prior design. Once our sales reps and customers tried the new applicator prototype at Fabtech and IMTS, the feedback was immensely positive. The greater precision and ergonomic benefits of the new applicator will be applied to the Model 850 as well.

The second is a cooling method guided by a continuous duty air pump inside the unit itself. The power of the 950 far exceeds that of prior models, so we wanted to prevent overheating at high power levels. We also wanted to maintain the portability of the Rocklinizer and avoid annoying constraints such as requiring an air source nearby. The continuous duty air pump was the answer, ensuring reliability and durability without restricting portability.

Results

The end result of the Rocklinizer Model 950 is similar to what our Rocklinizers have always produced: a reliable, precise carbide coating that generates exponentially greater machine life, substantially lower costs, and minimal downtime. The difference is now you can get there faster with a much greater range of deposit possibilities.

If you would like more information, a sample, or an on-site demo of the all new Rocklinizer Model 950, please contact us today.

Tags: rocklinizer , model 950 , electronic spark deposition , new products , carbide coating

« Back